Square Foot Efficiency

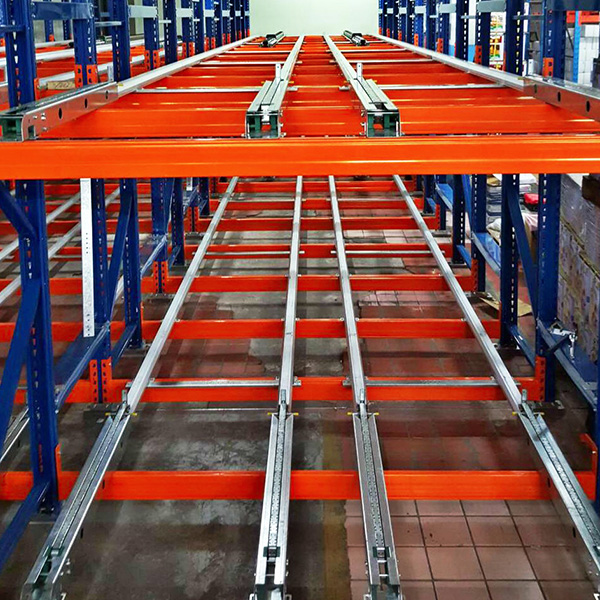

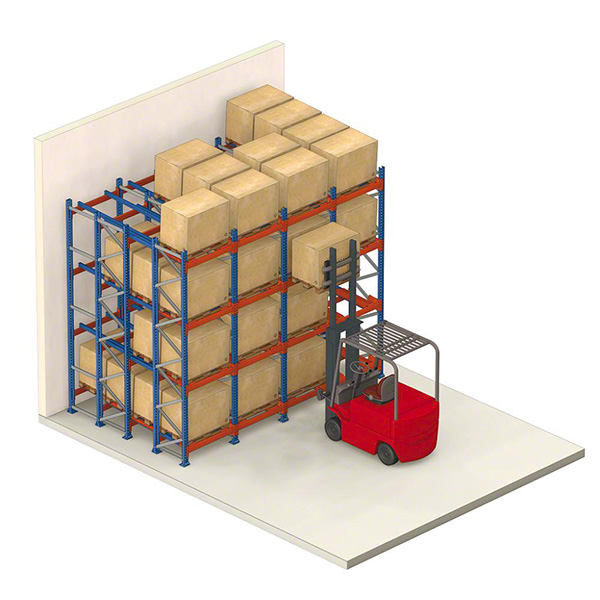

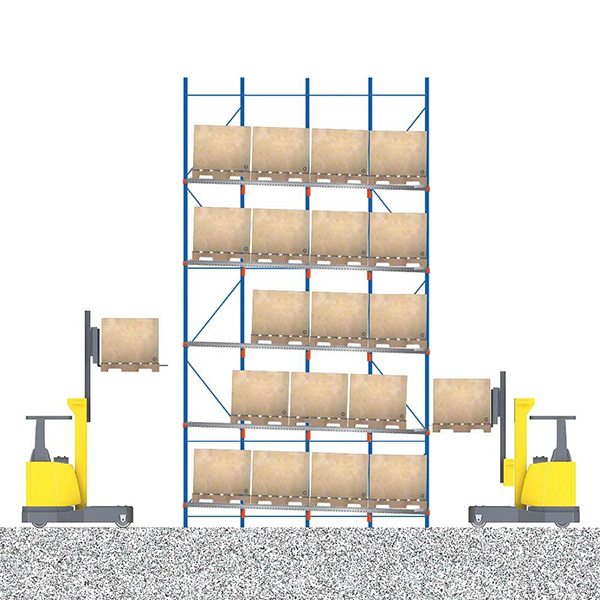

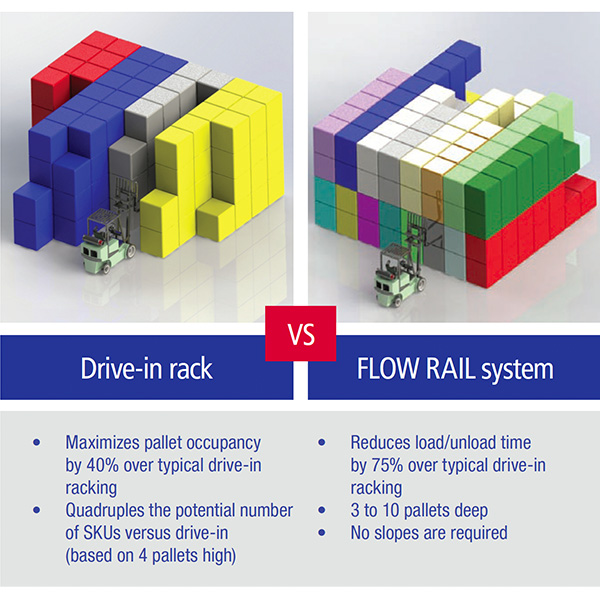

Flow Rail is the ultimate high-density racking system for pallets. Combining the flexibility of push-back with the density of drive-in systems, Flow Rail lets warehouse managers stock up to 10 pallets in the same lane, and mix different SKUs in the same bay. Goods can be picked individually from any level without having to empty the levels above and below. And unlike drive-in systems, which on average stand 40% empty because bays need to be fully emptied for effective stock rotation. Flow Rail makes each lane independent resulting in occupancy ratios in the order of 85%. Flow Rail also delivers more storage capacity in the same floor space. While push-back systems typically consist of lanes up to 6 pallets deep, Flow Rail lanes can hold up to 10. And since there’s no incline, there’s no wasted vertical space.

Safety

Accident risk is significantly reduced with Flow Rail. Operators upload and unload from the face of the rack, so there’s no driving in and out. Flow Rail keeps everything on a horizontal plane, which means less risk of individual boxes falling or drifting when pallets are in movement, thereby reducing product damages. Flow Rail also cuts down on structural wear and tear. Lift truck drivers don’t always report the damage they can cause when operating in drive-in tunnels. But accidental bumps can weaken structures and increase the risk of rack failure and injury.

Flexibility

Need more density? Flow Rail systems can be configured up to 10 pallets deep. And since no pitch is required, drive-in systems can be easily converted with Flow Rail using existing uprights. Flow Rail is also an effective way to keep pace with changing goods handling requirements. The system can store an impressive variety of products, regardless of shape or physical form. For extra large sizes, twin-loading multiple tracks can be used. A third rail can also be added for weak pallets or very heavy loads. Dimensional constraints on lift truck size for accessing drive-in racking are also eliminated. With Flow Rail, different size and model lift trucks can be used. It is very easy to extend or shorten the length of Flow Rail tracks. When made longer, 100% of the existing material is reused.

Trouble-Free Operation

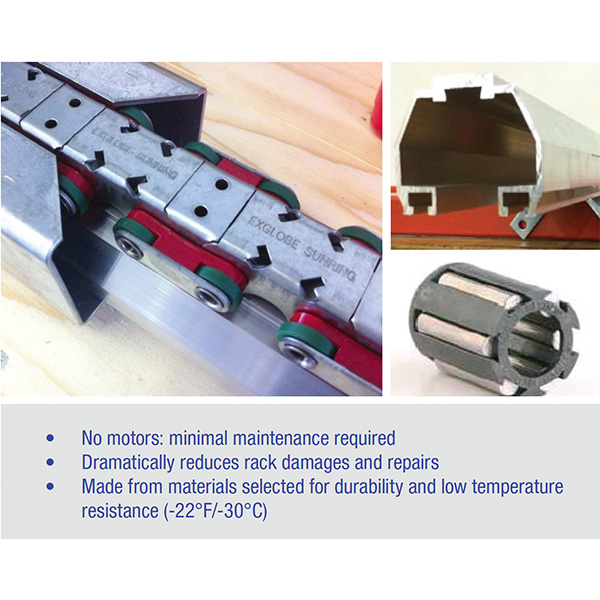

Flow Rail systems are manufactured using a fully automated process and top quality, low-temperature resistant materials for years of reliable, trouble-free performance. The risk of rack damage is also greatly reduced since lift trucks perform all pallet operations at the front of the rack instead of inside. For new projects, roll-form could be used instead of more costly structural steel.

Our experienced engineering and sales staff are here to offer expert advice on optimal warehouse layout and design. We focus on maximizing your storage capability while also taking into consideration your application and specifications. For additional information or to schedule a consultation, email us or give us a call today!